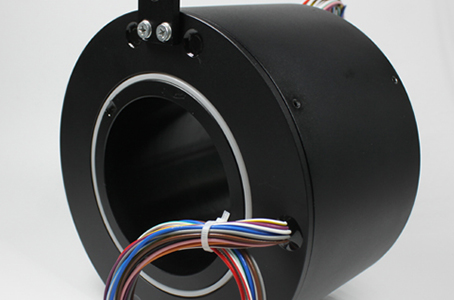

Slip ring has a different classification according to the structure, using area, transmission medium and so on. Through hole slip ring is mainly divided up from structure, could also called as hollow shaft slip ring, which mainly used for transmitting precision signal, weak current, large current and high voltage.

The use of the slipring is mostly for transmitting power or data signals with unrestrained continuous rotation from a fixed position to the turned position. Compared with other slip rings, its manufacture process and principle is similar, all of them transmit current, signal data through brush bundle and touch point contact from the stationary part to the rotary part.

The basic technical parameters of the hole type slip ring are outer diameter, inner diameter, length, number of rings, voltage, current, the highest speed, protection degree and so on. In the technical parameters of slip ring hollow shaft, length is variable and can be customized. However outer diameter and inner diameter have some standard size in the industry, such as through hole slip rings of Barlin Times have ten different series.

The inner diameter of the hollow shaft slip ring basically has 12.7mm series, 25.4mm series, 38.1mm series, such as range covers from 12.7mm to 180mm. Our standard through hole size could be from 12mm-190mm are optional. The number of rings rang covers from 1 circuit to 24 circuits, the standard circuits are 6 rings, 12 rings, 18 rings and 24 rings are available, the current can be alternative from 2A-800A. The number of rings is a very important parameter, is also the decisive factor of sliprings prices. Prices paid for different rings vary considerably.

Through hole slip ring is used in various field, mainly include medical equipment, turn table, rotary sensor, cable reel, packaging machine, test machine, engineering machinery equipment, environmental protection equipment and so on. In the future, through hole slip ring will be widely applied in automation equipment, automated testing equipment, automated robot, mechanical arm and other new areas. At that time, it will put forward higher requests for through bore slip ring on its structure and technical parameters. Therefore in the producing existing products at the same time, slip ring manufactures should invest research and development funds to design new products in order to adapt to the demand of the slip ring in the future.

Barlin Times